Download & Print

Instructions for the Manson Screw-In Choke Reamer

You’ve just purchased tools of the highest quality that, with care and proper use, will give years of good service and make money for your business. Many knowledgeable shotgun owners are asking that their guns be converted to the screw-in choke system and you can take advantage of this demand.

Before accepting a particular shotgun for this conversion, however, you need to determine if choke tubes may be installed. Many barrels are too thin and cannot be machined to accept the more common aftermarket choke tubes. There must be sufficient barrel wall thickness left after reaming/tapping for adequate strength so the choke tube will not be blown out of the barrel.

Fifteen thousandths of an inch (.015”) is generally considered the minimum wall thickness, at the thinnest point, for a successful installation.

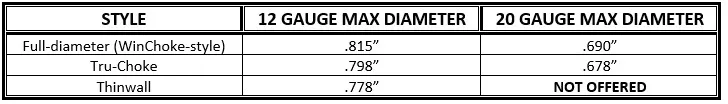

Because shotgun barrel thickness varies greatly, numerous aftermarket systems have been developed, with several becoming the most popular. Loon Lake Precision offers installation tooling for the three most popular systems as standard items (in 12 GA; 2 as std. in 20 GA) and can provide tooling for any system on special order. Standard systems, AND THE LARGEST DIAMETER THEY CUT, are given below:

For a shotgun barrel to be machined successfully to accept 12 Ga WinChoke tubes, the barrel must measure at least .845” outside diameter (.815” cutting dia. Plus 2x the min. wall thickness). This figure assumes that the outside is perfectly concentric with the inside – most often NOT the case. Because of this, YOU will have to use your judgment concerning the safety of a particular installation.

If installing WinChoke tubes seems questionable, consider a TruChoke or Thinwall installation. If the barrel seems too thin for any of these systems, it’s probably best to turn down the job. Please call us if you have any questions – we’ll be glad to provide any help we can.

Assuming you’ve decided an installation can be done safely and have the necessary tooling, machining of the barrel is done in the following steps:

- MAKE SURE THE GUN IS UNLOADED;

- Remove any existing choke;

- Ream the barrel:

- Tap the reamed barrel.

Special Note for Chrome-lined Barrels: Chrome plating is harder than reamer steel and can damage the reamer. Use cold-blue (Brownells; Oxpho Blue) to test for chrome – it will take on bare steel, it won’t on chrome. Call us if you run into this problem – several ways to get around it.

Remove Any Existing Choke: The object is to have a true cylinder bore from which the reamer and tap may be piloted. This will minimize any change in point-of-impact. Chokes can be removed by reaming, honing, or simply cutting off the end of the barrel.

Reaming the Barrel: This should be done under power, if at all possible. The eight flutes and large diameter of the choke reamer make it difficult to apply sufficient pressure for the tool to cut efficiently. The reamer can be used by hand, but it goes slowly and the tool will wear more quickly. If reaming by hand, place the barrel(s) horizontally so you can apply the most pressure and use a double-ended wrench (such as a large tap handle). DO NOT USE a bit brace – applying turning force to one side of the reamer can result in a bell-mouthed hole.

A lathe is the easiest way to ream the barrel(s). Instead of running the barrel(s) through the headstock – most won’t fit anyway – hold the reamer in a chuck or collet. The reamer’s pilot bushing will support the muzzle end of the barrel. To support the breech end, and to provide a way to push the barrel into the reamer, make a tapered plug that centers the chamber end and will reach past any barrel extension. Clamp this plug in the tailstock chuck.

The idea is to support the barrel between the reamer (in the headstock) and the tapered plug (in the tailstock), and push the stationary barrel into the turning reamer.

How to keep the barrel(s) from turning? Make a long-arm padded clamp that you place around the barrel(s). Your left hand holds the clamp to keep the barrel from turning while your right hand turns the tailstock spindle to feed the barrel into the reamer. Call if you’d like us to send you a print for this clamp.

Ream at 40-80 RPM and use plenty of good-quality cutting oil, stopping frequently to clear chips. Brownells’ Do-Drill or Rigid thread cutting oil both work well.

If you don’t have a lathe, you can turn this concept sideways and use a floor-mounted drill press, providing the spindle RPM is slow enough. Lower the table sufficiently so the barrel(s) you’re reaming will fit between the table and the drill chuck. Make (or have made) a tapered plug as described above, that fits the hole in the center of the drill press table. Hold the reamer in the drill chuck and place the breech end of the barrel on the plug. Again, make a long-arm clamp that will bear against the drill press column to prevent the barrel(s) from turning and ream the barrel by feeding the reamer into the barrel as if you were drilling it.

However you ream, install a pilot bushing that fits the bore as closely as possible to minimize any misalignment. Use plenty of good quality cutting oil and pause frequently to clear chips. Run the reamer in until the large diameter just squares up the end of the barrel. Remove the reamer, clean out any chips and you’re ready to tap – see separate instructions for this.

These tools, like all we manufacture, are warranted against defects in material and workmanship. If you have ANY questions, please call before risking a damaged gun or a ruined reputation.