The PROS Trust

Roy Huntington | Veteran Gunsmith![]()

The PROS Trust

Ken Thiessen | PRS & F-Class Competitive Shooter![]()

The PROS Trust

Marty Gunderson | Long Range & 300m Prone Shooter![]()

The PROS Trust

Chad Heckler | PRS Competitive Shooter![]()

Buy the Best to Build the Best

Manson Precision Reamers is the country’s premier supplier of chamber reamers, headspace gauges, and other cutting and gunsmithing tools for rifles, shotguns, handguns, and other firearms. Select a product category below or browse our online store.

PRS Collection

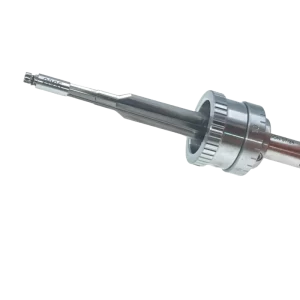

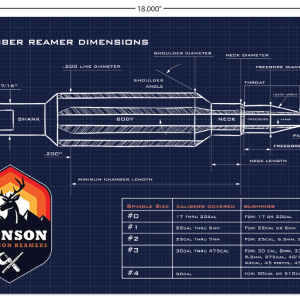

Chamber Reamers

Headspace Gauges

Cutting Tools

Muzzle Crowning Kits

Accessories

Shotgun Tooling

Receiver Truing

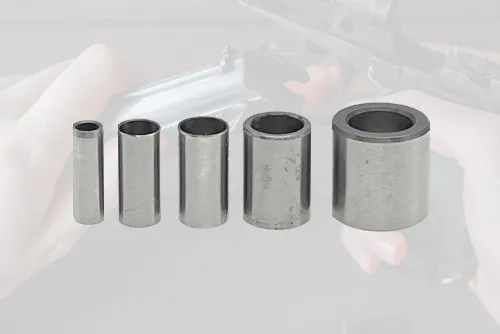

Pilot Bushings

Discounted Tools

Gift Certificates

Featured products

latest news

Carbide Reamers Are Here: What They Mean for Your Shop

For decades, Manson has been known for high speed steel chamber reamers that gunsmiths trust. They...

Manson Precision Reamers Partners with the Precision Rifle Series for the 2026 Season

Coming in 2026, Manson Precision Reamers is joining forces with the Precision Rifle Series as the...

Two Leading Gunsmithing Schools That Trust Manson Reamers

For decades, Manson Reamers has been a trusted name in the firearms industry — known for...

Chamber Reamers

Chamber Reamers Headspace Gauges

Headspace Gauges