CZ 457 Match Build: The Role of Lilja Barrels and Manson Reamers

Precision shooting starts with precision tooling, and for a few of us here at Manson Reamers, building match-grade .22 LR rifles has become more than a weekend project, it’s a way to test the results of our own craftsmanship firsthand. In this post, we’re highlighting our recent builds using CZ 457 actions paired with Lilja Match barrels, chambered using Manson Reamers. This wasn’t just about hobby rifles, it was about performance validation from the bench to the bullseye.

The Why Behind the Build

A few members of the team here at Manson Reamers, Steve K, Blake, and our friend Cody, are serious about rimfire accuracy. We each chose the CZ 457 as our platform for its reliability, user-friendly modularity, and consistent track record in .22 LR competition. It’s a rifle that responds well to upgrades, particularly in the barrel department, and it offers the kind of performance that’s easy to tune and hard to beat.

Our goal was to build out match-grade rifles that could stand up to serious accuracy testing. We all wanted to see, firsthand, how a Lilja barrel performs when chambered with a Manson Reamer.

Why Lilja Barrels?

Dan Lilja and his team at Lilja Precision Rifle Barrels have been producing world-class barrels since 1985. Based in Montana, Lilja is known for premium-grade button-rifled barrels that have been used by Olympic competitors, benchrest shooters, and military and law enforcement units alike.

For rimfire applications, Lilja offers .22 LR match barrels in a variety of contours and lengths. What sets them apart, beyond their material quality and precise rifling, is their willingness to match the right chamber design to the intended application, something that Manson Reamers is proud to be a part of. Lilja purchases all of their .22 LR chamber reamers from Manson, and we’ve worked closely to refine dimensions that consistently deliver match-winning performance.

It made perfect sense for us to see how the two components, Lilja barrels and Manson chamber reamers, performed together in the field.

The Manson Reamers Difference

Chambering is one of the most critical steps in building an accurate rifle. The geometry, finish, and concentricity of the chamber directly influence pressure, extraction, and ultimately, accuracy. At Manson Reamers, we design and manufacture chambering reamers to tight tolerances with a focus on clean cutting and consistent results. Our .22 LR Match reamers are no exception.

We supply Lilja with our 22 Match chamber reamers, which are designed specifically for competitive-level precision. These reamers are engineered for minimal bullet jump and optimal alignment between the case, bullet, and rifling. This is essential when you’re pushing for sub-MOA groups at 50 yards and beyond.

When you’re dealing with match ammunition, you want a chamber that holds it tight without excessive interference. That’s what our tooling is built for, and that’s exactly what went into these Lilja barrels.

The Build Details

Each rifle started with a CZ 457 action, known for its smooth bolt operation, modular trigger system, and easy barrel swaps thanks to its V-block bedding system. From there, we installed .22 LR Lilja Match barrels chambered with our own Manson 22 LR Match chamber reamers.

We hand-fit the barrels, torqued the actions, and confirmed chamber alignment before heading to the range. While each of us made our own decisions on optics, stocks, and other accessories, the core components—the action, barrel, and chamber—were uniform across the board.

From the very first outing, the performance was unmistakable, these rifles shoot!

Performance on the Range

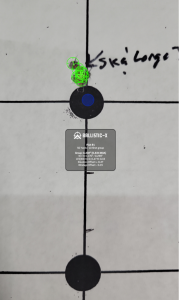

Our range days proved what we already suspected. The Lilja barrels, when paired with our chambers, delivered tight, repeatable groups. With match ammo like Eley Tenex and Lapua Center-X, we consistently saw five-shot groups well under half an inch at 50 yards, with many in the low .2s and .3s. Some of the best groups approached one ragged hole.

We were shooting off bags and bipods, with no special benchrest gear, just solid fundamentals and good conditions. The barrels cleaned easily, held zero between outings, and cycled reliably with our CZ bolts and aftermarket triggers.

Beyond the numbers, it was gratifying to see our tooling performing in the real world, not just on a lathe or inspection table. This kind of feedback loop, design, manufacture, chamber, shoot, is invaluable for refining our tools and pushing performance even further.

What We Learned

This project was more than just a test of rifle parts, it was a hands-on confirmation of what we do every day at Manson Reamers. We know that barrel quality matters, but so does the tooling used to bring it to life. A match-grade blank is only as good as its chamber, and a reamer is only as good as the groups it helps produce.

It also reinforced the quality of Lilja’s barrels. The machining, finish, and consistency were excellent across all the barrels we used, and the results on target made that obvious. As builders, shooters, and toolmakers, we couldn’t have asked for a better partner for this project.

Conclusion: Tooling You Can Trust

At Manson Reamers, our commitment to precision doesn’t end at the shop door. We believe in building tools that produce real-world results, and this project proved just that. Seeing our reamers in action, cutting chambers that perform at the highest level, is exactly why we do what we do.

Whether you’re a barrel manufacturer, a custom gunsmith, or a serious enthusiast chasing small groups, the right tooling makes all the difference. We’re proud to supply Lilja Precision Rifle Barrels with the chamber reamers that help define their performance, and we’re even prouder to shoot the results ourselves.

For more information on our rimfire match reamers or to discuss your next build, visit us at mansonreamers.com. And if you’re in the market for a premium barrel, we highly recommend checking out Lilja Barrels—their quality speaks for itself.