Introduction

When it comes to long-range shooting, precision and consistency are key. However, achieving both requires more than just skill; it demands meticulous firearm maintenance. One of the critical factors that can influence accuracy and performance is the condition of the barrel. Barrel fouling, fire cracking, and how they impact muzzle velocity are essential considerations for any serious shooter. In this article, we will delve into these factors and provide insights on maintaining your firearm for optimal performance. Special thanks to Applied Ballistics for their expertise with this comprehensive guide.

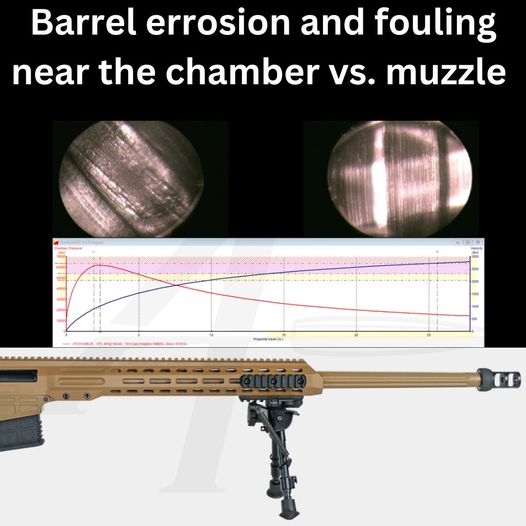

What is Barrel Fouling?

Barrel fouling refers to the accumulation of residue within the gun barrel after firing. This residue can include carbon deposits, copper from bullet jackets, and unburnt powder. Over time, this buildup can affect the smoothness of the bore, leading to variations in muzzle velocity and overall performance. Regular cleaning is crucial to maintain accuracy, especially for long-range shooting.

The Effect of Fire Cracking on Barrel Performance

Fire cracking is a phenomenon that occurs when tiny cracks develop in the barrel steel, beginning near the chamber end. This happens most severely where the heat and pressure are concentrated over the first several inches in front of the chamber. The severity of fire cracking varies based on things like the cartridge, steel quality, and ammo load. For example, a hot cartridge like 6 Creedmoor can develop fire cracking within 50 rounds, while a more moderate one like 308 Win might take hundreds of rounds.

How Fire Cracking Affects Muzzle Velocity

Interestingly, fire cracking leads to an increase in muzzle velocity. As cracks develop, they add friction, which resists the bullet’s travel down the barrel. This additional resistance causes the burning powder to burn hotter and faster, creating more pressure and ultimately increasing the bullet’s speed. Shooters often notice this as a new barrel ‘speeds up,’ thinking it’s the barrel smoothing out but the underlying reason is the increased friction due to fire cracking.

Why Regular Firearm Maintenance Matters

Maintaining your firearm is not just about ensuring its longevity; it’s about preserving accuracy and consistency. Proper firearm maintenance helps in controlling variables like barrel fouling and fire cracking, which increase muzzle velocity and reduce accuracy..

Here’s a quick breakdown of what regular firearm maintenance should include:

- Cleaning the Barrel Regularly: Removing carbon and copper fouling helps maintain a smooth bore.

- Addressing Fire Cracking: Using abrasive cleaning techniques can help smooth out fire cracks.

- Checking for Wear and Tear: Regularly inspect the barrel for signs of erosion and cracks.

Types of Barrel Fouling and Their Impact

There are two main types of fouling that shooters need to be aware of:

- Carbon Fouling: This is the buildup of carbon residues from the burning of gunpowder. It can quickly accumulate, causing friction and reducing accuracy.

- Copper Fouling: Copper deposits are left behind by the bullet jacket. These deposits can be especially problematic, as they can increase resistance and affect muzzle velocity.

Both types of fouling need to be managed to maintain performance, especially when long-range shooting.

Cleaning Techniques for Different Firearms

Depending on the type of firearm and its usage, the cleaning method can vary. For moderate chamberings like 223REM or 308WIN, using chemical solvents that dissolve carbon and copper fouling might be sufficient. However, for high-performance firearms like 300 Norma or 6.5 PRC, abrasive cleaning is recommended.

Recommended Cleaning Procedure for High-Performance Guns:

- Start with a Lightly Oiled Patch: Push it through the barrel to remove loose debris.

- Apply JB Bore Paste: Use a very tight-fitting patch to smear a healthy amount of JB Bore Paste (blue/gray).

- Use 30 Strokes Back and Forth: Focus more on the chamber end, where fire cracking is usually severe.

- Remove the used patch and repeat Steps 2-3

- Finish with Oily and Clean Patches: Ensure that all abrasive residues are removed.

This method was refined during lifecycle testing on high-performance rifles, including the 375 EnABELR and 300 Norma at Applied Ballistics, showing that abrasive cleaning does not excessively wear out barrels as some shooters fear.

The Science Behind Barrel Erosion and Muzzle Velocity

Barrel erosion is the gradual wearing away of the inner barrel surface due to heat, pressure, and friction. When coupled with fouling, it can lead to erratic muzzle velocity and affect shot precision. For shooters aiming for consistency in long-range shooting, managing barrel erosion is also essential.

Here’s how erosion affects performance:

- Increased Friction: As erosion and fire cracking develop, they elevate friction, which increases muzzle velocity.

- Heat Accumulation: The more friction there is, the more heat accumulates, leading to faster burning powder and higher pressure.

- Variable Bullet Speed: Irregularities in friction and pressure can lead to inconsistent bullet speeds, affecting accuracy.

Abrasive Cleaning vs. Chemical Solvent Cleaning

There’s an ongoing debate about the best way to maintain firearm barrels. While chemical solvent cleaning effectively removes carbon and copper, it might not address the fire cracking that contributes to friction and velocity changes. Abrasive cleaning, on the other hand, helps smooth out fire cracks, providing a more uniform bore surface and reducing the friction.

Collaborating with Applied Ballistics for Accuracy Science

At Applied Ballistics, the science of accuracy is at the forefront of everything they do. Their extensive research and testing help shooters understand how factors like firearm maintenance, muzzle velocity, and long-range shooting accuracy are connected. Their collaboration on this article has provided valuable insights into effective cleaning techniques and understanding barrel behavior.

Practical Tips for Long-Range Shooters

- Clean Your Barrel After Each Shooting Session: Regular cleaning helps prevent excessive fouling buildup.

- Use Abrasive Cleaning for High-Performance Rounds: If you’re shooting hot cartridges, consider using an abrasive to address fire cracking.

- Monitor Barrel Wear: Keep track of how your barrel behaves over time and inspect for erosion and fire cracking.

- Understand Your Firearm: Knowing how your specific rifle and cartridges interact can help you decide which maintenance approach is best for you.

Conclusion

For enthusiasts of long-range shooting, understanding the impact of barrel fouling, fire cracking, and muzzle velocity is crucial. Effective firearm maintenance not only enhances the longevity of your equipment but also ensures consistent and accurate performance. By following the cleaning and maintenance strategies outlined above, shooters can maintain their firearms in top condition.

Thanks to Applied Ballistics for providing expert insights on the science of accuracy. Follow these tips to keep your rifles performing at their best, and ensure you can make those long-range shots count.

FAQs:

- What causes fire cracking in rifle barrels?

- Fire cracking occurs due to extreme heat and pressure, leading to tiny cracks forming near the chamber end of the barrel.

- How does barrel fouling affect muzzle velocity?

- Barrel fouling increases friction, which elevates muzzle velocity due to hotter and faster powder burn.

- Should I use abrasive cleaning for my firearm?

- If you’re using high-performance rounds, abrasive cleaning can help smooth fire cracking and maintain a consistent bore.

- What is the best way to clean carbon and copper fouling?

- Use chemical solvents for moderate fouling and consider abrasive cleaning for tougher buildup, especially in high-performance firearms.

- Why does my new barrel ‘speed up’ after a few rounds?

- The increase in muzzle velocity is often due to the added friction from developing fire cracks, not just barrel smoothing.

By following these guidelines, you can optimize your firearm’s performance and ensure accurate, reliable results for your long-range shooting endeavors.