Buy the Best to Build the Best

Manson Precision Reamers is the country’s premier supplier of chamber reamers, headspace gauges, and other cutting and gunsmithing tools for rifles, shotguns, handguns, and other firearms. Select a product category below or browse our online store.

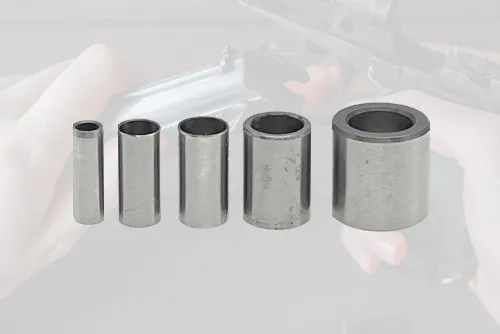

Pilot Bushings

Chamber Reamers

Headspace Gauges

Cutting Tools

Muzzle Crowning Kits

Accessories

Shotgun Tooling

Receiver Truing

Featured products

latest news

Check back to our website often to get the latest news from Manson Precision Reamers including upcoming events, new product launches, sales and promotions.

Manson Reamers 2023 Christmas Schedule

This year Manson Reamers will be closed from 12/25/2023 (Christmas Day) - 01/01/2024 (New Year's...

Manson Reamers Visit Gordy Gritters’ Extreme Accuracy Institute

Manson Reamers goes to Florida! The team at Manson Reamers took a special trip down to Florida to...

Thank you Dave Manson!

On April 12th, 2023 we recognized Dave Manson for the many years of dedication to the company.

Chamber Reamers

Chamber Reamers Headspace Gauges

Headspace Gauges